At Post Precision Castings, Inc. we have a modern, well-maintained 125,000 square foot facility that includes a high degree of automation, computerization, and support systems. We are recognized for the personal attention that we give our customers, and have a high level of commitment to quality and constant improvement. With full control of the production process, we can build the tool, manufacture the castings, and machine the castings all in one facility. We provide high-quality investment castings in 100 alloy steel compositions, including stainless, alloy steels, superalloys, copper nickel alloys, gray iron, bronze, and numerous corrosion resistant alloy steels. We can produce between 1 and several thousand castings, as well as castings ranging in weight from 1 ounce to 250 pounds. Our production capabilities include: ceramic cores, soluble wax cores, automatic wax injection machines, robotic ceramic shell building procedures, and automated grinding.

Tooling and Machine Shop

- In-house tool and die shop – Keeps overall costs low and short lead times!

- With in-house tool and die shop, we have the ability to:

- Build new tools

- Modify and repair tools as needed while in production

- Alter an existing tool in order to realize its full potential and save production costs

- Produce a metal or wax sample from supplied tooling for customer inspection in as little as two to three days (wax) or two weeks (metal)

- Allows for turnkey Operation

- Low cost injection molds

- Electrical Discharge Machine (EDM) – used to machine hard metals which are difficult to machine using conventional techniques. EDM allows for cutting small or odd shaped angles

- We provide electronic drawing file transfer using commercial file formats such as solid, IGES and DXF. All tooling quotes are based on the customer providing commercial file formats for Post to build or alter tooling/injection molds. Post reserves the right to re-quote orders where commercial files are not available.

- CNC Vertical Machines (Bridgeport VMC 760 picture)

- We operate a full service machine shop for small and large lot runs and we utilize excellent local machine shops if need be

Engineering

- Our experienced technical support personnel are available to intelligently discuss areas like tooling, alloy selection, specifications, our process, machining, etc. Our staff is trained to minimize production problems and assure that your needs are properly met.

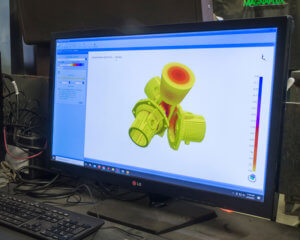

- We utilize the Mastercam CAD format for the quality review of common problem areas such as flatness, parallelism, straightness, and roundness.

- We have an extensive selection of alloys

- Design flexibility for internal and external configurations

- We are able to produce rapid prototypes

Finishing

- In-house Heat Treat services

- We also utilize reputable local heat treat providers

- TIG and MIG Welding

- In-house Kolene salt bath unit to economically leach and thoroughly clean ceramic material from hard to access internal core areas

- Final Cleaning Options:

- Pickle Finish

- Aluminum Oxide Finish

- Glass Bead Finish

- Iron Shot Finish

- Shipping Options

- Cardboard Container

- Cardboard Drum

- 55 Gallon Metal Drum

- Wooden Crate

Alloy Specification Chart

- Depending upon your order’s pour weight, Post Precision Castings, Inc. offers 300, 500 and 1,000 pound furnaces to efficiently pour the minimum metal weight that keeps your metal costs as low as possible.

- View Our Available Alloys

Performance

- Low casting defect rate of .006% of casting sales

- We offer Kanban – short terms delivery programs for higher volume parts

- Our Company regularly exceeds our customer’s 95% On Time Performance (OTP) expectations

Markets Served

Food And Beverage Processing

Food And Beverage Processing

Pharmaceutical Processing

Material Handling Equipment Fluid Handling Applications

Fluid Handling Applications

Pumps And Valves

Seals Chemical Processing

Chemical Processing

Petrochemical Processing

Pulp And Paper Processing Construction Industry

Construction Industry

Agricultural

General Machinery Oil And Gas

Oil And Gas

Power Generation

Nuclear Applications

Fittings And Assemblies General Industrial Machinery And Equipment

General Industrial Machinery And Equipment

Recreational Equipment

Rail Industry

Military And Defense